Crushmaster Marine presents the

CM-ONE at the "Metstrade 2021"

Crushmaster Marine presents the CM-ONE at the "Metstrade 2021"

From November 16 until November 18, 2021 at the Metstrade trade fair in Amsterdam. Come and see the CrushmasterCM-ONE live in action. We look forward to seeing you at Metstrade 2021, booth no. 05.853.

See crushmaster at "boot 2022"

See crushmaster at "boot 2022"

We will be exhibiting at the boot 2022 from 22 to 30 January 2022 in Düsseldorf (Germany). Come and see the Crushmaster CM-ONE live in action. The solution for the treatment of waste on sailing yachts. By shredding and vacuuming of the waste, the space and storage requirements of the waste are enormously reduced and the possible odor nuisance is avoided. The effort for the subsequent disposal of the waste is also minimized. We look forward to seeing you at the boot 2022, Hall: 10, Stand No.:10A47

Onboard waste processing

Onboard waste processing

During longer voyages, new waste is generated on board every day that cannot easily be disposed of in the next port. The onboard waste increases with each passing day, takes up storage space and may even start to smell unpleasant. When embarking on longer journeys it is necessary to address the subject of waste disposal and processing. This is exactly what Crushmaster Marine has learnt from its own experience of longer passages and has developed a new solution for waste management onboard.

Crushmaster Marine has set itself the goal of reducing the volume of waste onboard medium-sized to large yachts and thus aiding the proper disposal of waste and keeping the oceans clean for everyone.

Thanks to many years of experience in the recycling industry and the processing of plastic waste, Crushmaster Marine has developed a new device specially designed for shredding waste on board, the CM-ONE, for maritime use.

The process:

In the CM-ONE device, the first step is to feed the waste through a feed chute for shredding. There the waste is crushed into small chips and diposited in a collecting bucket with a clamped plastic bag.

During the second step, the plastic bags are vacuum sealed, which further reduces the volume and the required storage space in addition to sealing in and bacteria and odours.

The vacuuming of the waste not only makes handling easier, it is also more hygienic and there are also no problems with insects and flies when disposing of it in port.

Commercially available vacuum bags can be used for vacuuming soft materials such as plastics. As an option, Crushmaster also offers special plastic bags that are extremely tear-resistant. Harder materials such as glass and sheet metal can also be vacuum-sealed.

If the shredded waste is vacuumed, the waste does not have to be cleaned separately beforehand.

CM-ONE is available as a single solution, for subsequent installation or as an OEM version for yacht construction.

Is also suitable for installation in existing cabins or the galley similar to a dishwasher or refrigerator.

Benefits:

- Volume reduction up to 80% (depending on material and properties)

- Small footprint

- Various options

Areas of application:

- In the cabin, galley

- In the storage room, storage space

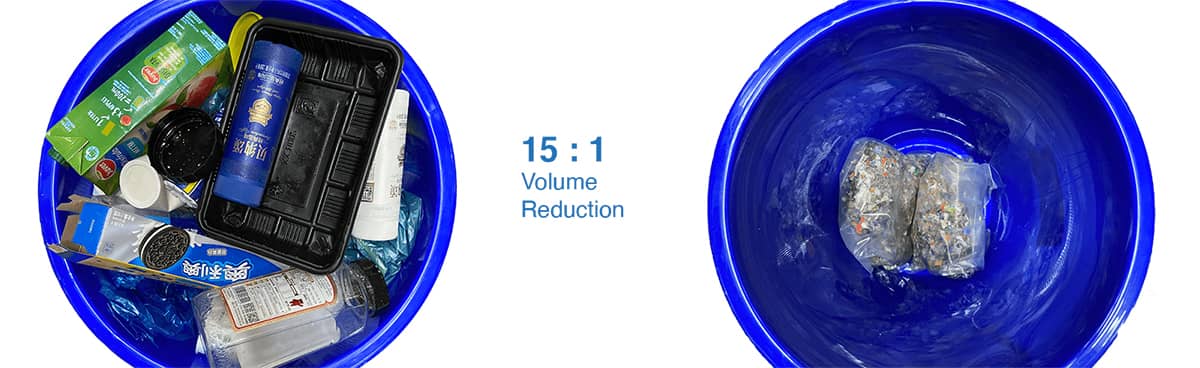

Volume Reduction

Volume Reduction

The Crushmaster Marine CM-ONE enables waste to be reduced by a factor of around 15: 1. The content of 60 litres of waste can be reduced to approx. 4 litres. The resulting waste is simply fed into a feed opening and then shredded. The dead space is greatly reduced by the high degree of shredding.

Annoying work such as cutting up the waste with scissors is no longer necessary.

Designed for typical on-board waste

Designed for typical on-board waste

CM-ONE is designed for all types of typical waste onboard, e.g. plastic, bottles, plastic packaging, composite packaging, paper and plastic films.

The waste can be deposited separately or mixed. Various options are available for harder materials.

Details

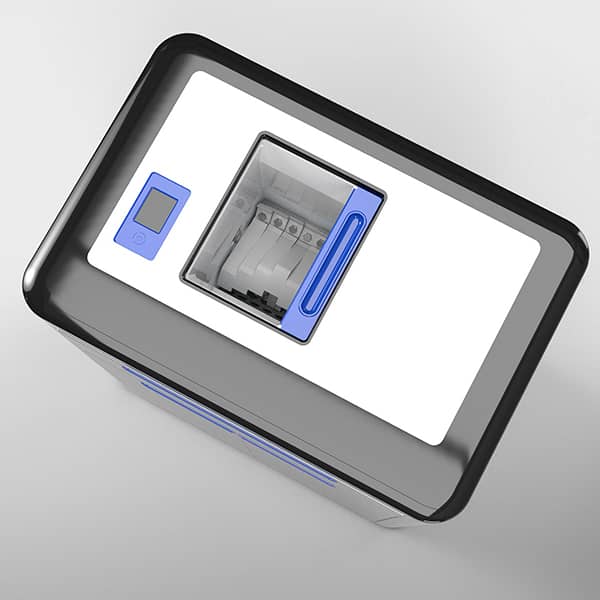

The CM-ONE is a two-stage system, consisting of a shredding unit combined with an integrated vacuum system. The on-board waste is automatically shredded after being fed through the feed shaft. An intelligent control system avoids blockages or material jams in the shredding unit.

The shredded waste is collected under the shredding unit in a collecting container with a clamped vacuum bag. When the collecting container has reached its fill level, the collected, reduced waste is vacuumed up in the vacuum bag with the integrated vacuum sealer. The waste is compressed even further by vacuuming and hermetically sealed. This also prevents odours and bacteria from developing.

Downloads

For more information, measurements and power requirements about the CM-ONE you can download the latest version of the brochure as pdf:

Download brochure

PRESS REPORT (04.2021)

Crushmaster Marine: Wastemanagement on High Seas

The newly developed, patented, two‐step waste processor “CM-ONE”

Download Press Report